REMOTE MONITORING OF LPG TANKS LEVELS

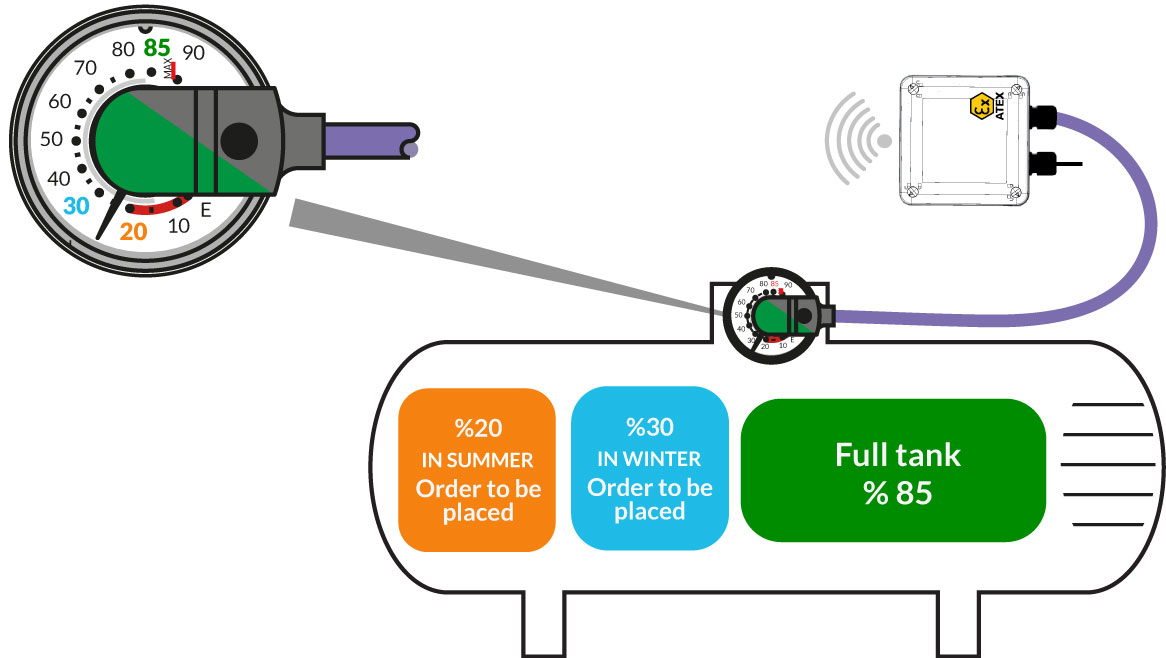

Remote monitoring of fixed or mobile tank levels using information from the Rochester gauge via the LoRaWAN network

How to keep track of the level in LPG tanks at any time so as to predict when they need to be refilled?

Solution

Lev’O+ LPG Level is a remote reading solution based on the autonomous battery-powered Toran’O sensor associated with a Rochester probe. Measurement data is transmitted periodically over the public or private LoRaWAN network to the remote application.

The system can be easily installed on all types of LPG, propane, butane and other gas tanks in AtEx Zone 1 environments.

Lev’O+ LPG Level allows the remote reading of other information such as volume metering or status report.

By remotely monitoring the level present in tanks, distributors and maintainers are able to plan and optimise deliveries of Liquefied Petroleum Gas (LPG) to various consumers more efficiently.

New or retrofit installation: Rochester Hall effect gauge

In order to monitor the consumption and the date of a refill, LP gas tanks are fitted with level gauges designed for magnetic drive dials that provide a simply means to check the quantity of gas present in the tank. The magnetic drive feature allows a signal from the float mechanism placed inside the tank to be transmitted through a solid bulkhead to the dial.

These dials can be substituted by the Rochester Hall effect transmitter, the principle of which is based on the transformation of the magnetic field from the dial indicator magnet into an electrical signal proportional to the volume of liquid inside the tank.

These Rochester transmitters are available with different dial sizes (Junior, Senior). (Refer to the documentation specific to each model).

The advantage is that they can be retrofitted on existing tanks to provide an electrical output that can be used for remote tank level monitoring.

References:

- Rochester 6320S81072E (junior)

- Rochester 6320S91072E (senior)

Description of the Lev’O+ solution: Rochester gauge connected to the Toran’O sensor

The Toran’O sensor is certified for use in an AtEx Zone 1 explosive atmosphere.

It has two 0-5 V analog inputs and a 5 V power supply used for its connection to Rochester gauges.

The sensor inputs are configured as ratiometric and return a percentage of the supply voltage (measurement = % Vin). The gauge integrates internal electronics and contactless Hall effect technology, and converts magnetic field variations into a ratiometric voltage output. A 3-wire cable connects the voltage output of the Rochester transmitter to the input of the Toran’O sensor and transmits the gas level. The gauge is fitted with a dial located outside for direct reading. For gas level reading using an AtEx certified Rochester gauge, the Toran’O sensor powers the gauge for the duration of the measurement and reports the analog quantity measured over the LoRaWAN network.

The range and accuracy are those given by the gauge (see gauge data sheet).

Battery autonomy:

Based on 1 transmission per day, the battery life is > 10 years.

Based on 1 to 4 transmissions/day uploading 1 measurement every 6 hours, the on-board battery life is at least 8 years.

The sensor can be used over public networks (Orange, Objenious) or over a private network (gateway).

Connection to the Toran’O sensor

The accessory designed for use with gas tanks needs to be added: ROCHESTER gauge (Senior or Junior) connected to the Toran’O transmitter sensor. The Toran’O housing includes an Amphenol female connector for the removable male connector on which all the connection points are located.

WATTECO, your IoT partner

Over 30 years of experience

in the design, development, industrialisation and manufacturing of electronic products

Integrated design office

to develop new concepts according to your constraints

Made in France

our production workshop is based in Hennebont (56), France and the company is ISO 9001 certified